Proactive Leak Detection Strategies

Pressure Testing for Hidden Weaknesses

Testing for pressure changes remains one of the best ways to find those pesky radiator leaks that just won't show up during regular inspections. When we pump air into the cooling system, anyone watching closely will notice when the pressure starts dropping off, which basically tells us there's a leak somewhere. Doing these pressure checks regularly catches problems early on before they turn into big headaches down the road, saving both money and time spent waiting for repairs. Most mechanics recommend doing this check once every year minimum, though some folks prefer to run it whenever their car gets routine service. Keeping up with pressure tests makes all the difference in how well the radiator works over time and prevents those unexpected breakdowns nobody wants to deal with.

Identifying Compromised Hoses and Connectors

Keeping hoses and connectors in good shape matters a lot when it comes to radiator systems staying intact. A quick look at those parts every now and then for things like cracks, swelling spots, or weird color changes helps stop major coolant leaks before they happen. Let's face it, nobody wants their car overheating and causing expensive engine problems down the road. Doing regular checks and swapping out old parts before they fail actually makes the radiator work better and cool more efficiently. Some mechanics swear by having a written list of what to check each time. This simple trick keeps nothing slipping through the cracks during inspections. Taking care of these basic components really does protect the radiator from sudden breakdowns that could leave anyone stuck on the side of the road.

Enhancing Thermostat & Water Pump Functionality

Recognizing Flow Restriction Symptoms

Knowing when something's wrong with coolant flow matters a lot if we want our cars running properly. Watch out for things like engines getting too hot, temperature gauges acting all over the place, or heaters that work sometimes but not others these might mean problems with either the thermostat or water pump. Checking the temperature gauge regularly helps catch small issues before they turn into big headaches down the road. When there's suspicion about restricted flow, doing a simple flow test makes sense. If the water isn't moving through as fast as it should be, that usually means something's clogged up somewhere important. Fixing these kinds of problems right away protects the radiator and keeps the whole car running better without creating bigger troubles later on in other parts of the system.

Preventative Replacement Intervals

Regular replacements of thermostats and water pumps are essential for keeping a car's cooling system working properly over time. Most mechanics suggest swapping out these parts somewhere between 60k and 100k miles mark, though exact timing depends on what the carmaker says and how hard the vehicle gets used day to day. Smart drivers track when these components go in so they can swap them out before problems start showing up. This proactive approach saves money down the road because failed parts often lead to expensive fixes or even total radiator damage. Extreme weather conditions matter too. Cars driven regularly in very hot climates or freezing temperatures tend to wear these parts faster than those kept in moderate environments. Knowing this helps determine when it makes sense to replace components ahead of schedule.

Upgrading for Superior Thermal Management

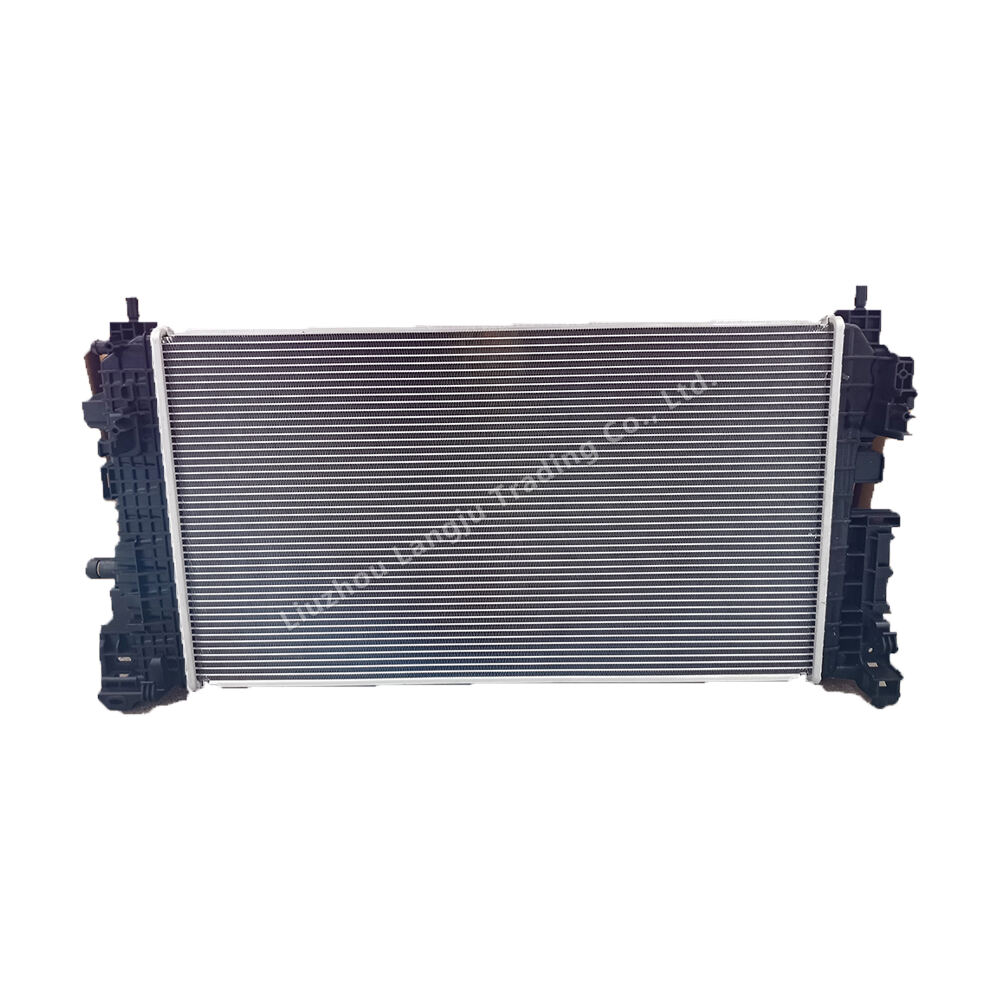

High-efficiency Radiator Configurations

High efficiency radiators make all the difference when it comes to keeping things cool inside an engine bay. They're built with better materials and clever designs that actually expand the surface area available for heat transfer, which means they can pull more heat away from components before it causes problems. For anyone looking at upgrades, radiator core thickness matters a lot, along with how everything fits together mechanically. This becomes really important during those long highway drives or when towing something heavy, where regular cooling systems just aren't enough. A good high flow radiator works wonders for modified engines or performance builds specifically because these engines generate so much extra heat. The increased cooling capacity helps maintain safe operating temperatures even when pushing hard, which protects expensive parts from warping or failing prematurely.

Enhanced Cooling Components for Modern Engines

Modern engines need better cooling parts because they're pushing harder than ever before with all that extra power and running at much tighter tolerances. When engines crank out more horsepower, they also throw off way more heat. That's why folks are turning to things like high performance water pumps and newer thermostat designs these days. Investing in quality cooling fans and proper fan shrouds makes a big difference too. The airflow gets improved substantially, which means radiators work their magic more efficiently. All these improvements help the cooling system handle those intense thermal demands without breaking a sweat, ultimately keeping engines running smoother for longer periods between major overhauls.

Optimizing Airflow for Peak Performance

Debris Removal Techniques for Radiator Fins

Keeping radiators running at their best starts with cleaning those tiny metal fins that get blocked up by all sorts of stuff - dirt, leaves, even bits of twigs sometimes. When left alone, this junk builds up and makes the radiator work way harder than it should. The trick is gentle cleaning methods since those fins are pretty fragile. Most folks find that a soft brush works wonders, though some swear by compressed air cans too. Anyone working around construction zones or farms knows how fast things get dirty out there. That's why smart operators check their radiators weekly during busy seasons. A quick look-over saves headaches later when engines start running hot because the cooling system just can't breathe properly anymore.

Fan Operation Diagnostics and Improvements

Getting the fans working properly makes all the difference when it comes to good airflow and proper cooling inside the radiator system. When troubleshooting, look at how fast the fan spins, listen for unusual noises, and check if it reacts correctly when temperatures rise. Switching from old school mechanical fans to electric ones generally gives better results because they respond faster and work more efficiently overall. Adding a fan shroud around the setup helps push more air directly through the radiator core too. All these fixes do more than just move air around though. They actually extend the life of the whole system while making sure engines stay cool even during long drives on hot days or when stuck in traffic.

Seasonal Maintenance & Monitoring Habits

Summer/Winter Preparation Checklist

Getting ready for seasonal changes means giving your radiator some attention before problems pop up out of nowhere. Most folks tend to grab their tools and check coolant levels first thing, then look at those old hoses and make sure the thermostat actually works when needed. Summer brings extra heat so checking the cooling system more often makes sense, especially after long drives or when temperatures spike unexpectedly. Winter tells a different story though. Cold weather demands proper antifreeze concentration to stop pipes from cracking when temps dip below freezing point. Stick with regular maintenance through all seasons and radiators perform better overall. Plus nobody wants to deal with expensive fixes right before Christmas because someone forgot about the car sitting in a garage during December snowstorms.

Developing Effective Temperature Observation Routines

Keeping an eye on engine temps isn't just good practice, it's essential if we want our vehicles running at their best. From my experience, setting up a regular check schedule catches problems before they become serious headaches. Digital gauges give much better readouts than old school methods, so when things start getting hot, we spot it faster. I also keep records of all these temperature readings over time. Looking back through this data often reveals patterns that point to bigger issues with the cooling system down the road. The whole point is creating habits that let us stay ahead of potential breakdowns while keeping everything running smooth and efficient without surprises.

FAQ

Why is pressure testing important for my radiator system?

Pressure testing is crucial because it helps identify leaks within the radiator system that may not be immediately visible. Regular pressure tests can detect hidden weaknesses, preventing major issues and ensuring efficient radiator performance.

How often should I replace my thermostat and water pump?

The recommended replacement interval for thermostats and water pumps is every 60,000 to 100,000 miles. Adhering to manufacturer guidelines and considering usage conditions will help prevent potential radiator issues.

What are high-efficiency radiators and why should I consider them?

High-efficiency radiators are designed to optimize thermal management by enhancing heat dissipation. They use advanced materials to improve cooling capacity, especially beneficial for high-performance engines, ensuring optimal temperature ranges.

How can I optimize my radiator's airflow?

Optimizing airflow involves regular cleaning of radiator fins to remove debris and upgrading fan systems to ensure efficient cooling. Implementing fan shrouds and periodically checking for air blockages can enhance airflow and radiator performance.